Excavator chassis is a crucial component of excavator machinery, and it plays a significant role in enabling the excavator to perform its various functions efficiently. The excavator chassis consists of several key parts that work together to ensure the mobility and stability of the excavator.

The most critical part of the excavator chassis is the track assembly, which is made up of tracks and undercarriages. These undercarriages are built to handle the weight and pressure of the tracks, which are in turn responsible for the machine's movement. The tracks are designed to grip the ground and provide stability and traction, enabling the excavator to move forward, backward and sideways.

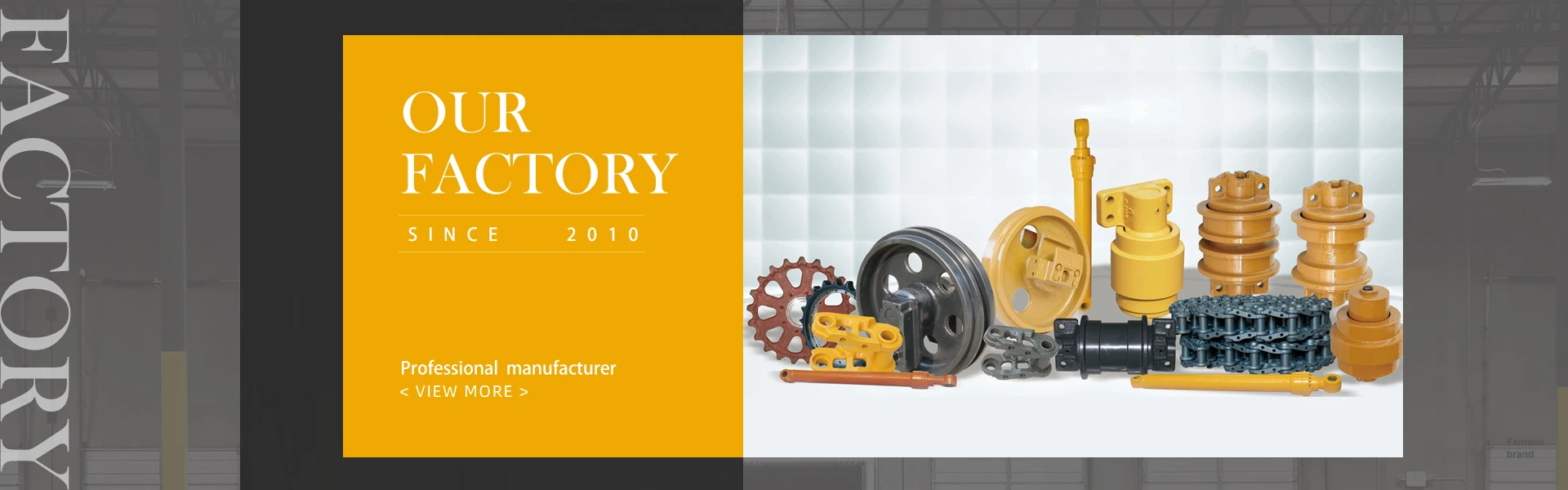

The excavator track assembly also comprises idlers, sprockets, and track rollers. The tracks rotate around the sprockets, which propel the excavator's motion. The idlers are responsible for indexing the tracks and maintaining proper tension. Meanwhile, the rollers hold the tracks in position, reduce track vibration and improve stability.

The excavator chassis also includes the cab, the engine, and the hydraulic system. The cab houses the operator and all the controls that run the excavator's operations. The engine provides the power that drives the entire machinery, while the hydraulic system is responsible for the excavator's functions, such as digging, lifting, steering, and extending.

Maintaining an excavator's chassis is essential for the optimal functioning and longevity of the machine. Regular inspection, servicing, and replacement of worn-out parts are crucial in ensuring the excavator performs effectively.

In summary, the excavator chassis is an assemblage of several indispensable parts that enable the excavator to perform its various tasks efficiently. Proper maintenance of the chassis and its components is necessary to keep the excavator running seamlessly, providing quality service for years to come.

Excavator chassis components

Nov 13, 2023

Send Inquiry