CAT345GC Track Adjuster Assy

Type: Excavators

Model: CAT345GC

Weight: 221 Kg

Brand: CATERPILLAR

Type: Excavators

Model: CAT345GC

Weight: 221 Kg

496-2993 TRACK ADJUSTER ASSY

Compatible with the following machinery

336 336 GC 340

345 GC MD6200

5 Simple Tips for Maintaining Your Track Spring Assembly

As a part of the undercarriage, the track spring (recoil spring) assemblies on your excavator, dozer, or other tracked machine can often only gather attention when they stop working correctly, but keeping them well-maintained and operating properly isn't just a benefit to the track spring assembly, it's an asset to the entire undercarriage. To help us all keep a sharp eye on this part, we've put together these five fast, short tips for track spring assembly maintenance.

First, it's important to note that the track spring assembly plays a dual purpose on your machine: keeping proper tension in the track and protecting other parts from impacts. The track spring assembly does its job though a track tensioner that generally consists of a cylinder that adjusts the position of the idler wheel and a recoil spring that absorbs impacts and prevents undue force being applied to delicate parts like the final drive.

Learn all about track springs in our What Are Track Springs post. With that in mind, we can jump into our maintenance tips.

1 Keep a Clean Undercarriage

Nobody's favorite part of the job on a construction site is cleaning the machines and the undercarriage can seem like it should always have a good coat of dirt on it, but routinely cleaning the undercarriage and making sure the track spring assembly isn't full of dirt or important parts aren't hidden under a layer of grease helps to keep parts working properly and makes signs of trouble brewing simpler to spot.

2 Routinely Inspect Your Track Spring

If you're a frequent reader of this blog, you know when it comes to maintenance we're fully behind an 'always watching' approach. For your track springs an extra level of close inspection is important and can be done fairly quickly.

First, look at the recoil springs and make sure they aren't broken, warped, or cracked. A sudden break in a recoil spring can be dangerous as they are under pressure and even though your machine might seem like it's working fine with a broken spring, it's actually lost an important safety component for other parts.

Next, inspect grease valves and seals. If grease is leaking out of the cylinder it's a clear sign the seal is failing and though the failure might seem small at first it can lead to a larger loss of tension and sudden and dangerous troubles in your track.

3 Match Your Track Tension to Your Working Environment

One of the benefits of tracked machines is their adaptability to a wide range of working and ground conditions and environments. The stability of tracks in loose materials, wet conditions, and rough ground is unmatched, but tracks work best when the tension is set to match the environment in which they are working. Even cold environments or ground prone to load the tracks with mud can change how the tension of tracks should be set. And simply keeping the tracks at proper tensions will keep your track spring assembly in good working order and extend the life of your tracks

4 Test Your Track Tensioner

In the previous tip we suggested frequently adjusting your track tension to match your environment, but maybe your machine works day after day in the same site and nothing much changes that would need track adjustments. If that's the case, you should still periodically use your track tensioner to tighten and then loosen your track. Routine use will allow you to be sure nothing has seized, watch to make sure movements are smooth and fluid and your piston isn't stuck or bent, and ensure your grease valves take grease.

Every excavator will need to have its track adjusted sometime and routinely ensuring your track spring assembly works properly at all times is a simple way of making sure when that day comes it's up to the job.

5 Run Your Machine Like the Pro You Are

You're reading an article on track spring assembly maintenance tips -- it's probably safe to assume you're the kind of operator who treats their machine right. For the sake of repetition though, it's always important to remember that how you run your machine will affect the life of parts and how they function. There's always a fine line between getting the most out of your machine and throwing all caution to the wind, but finding that line is a sign of an expert operator.

Ensuring you avoid overly repetitive movements, stay away from too much reverse action, and avoid running your machine when the tracks are too loose or tight are the basics of maintenance for your track spring assembly and your entire undercarriage.

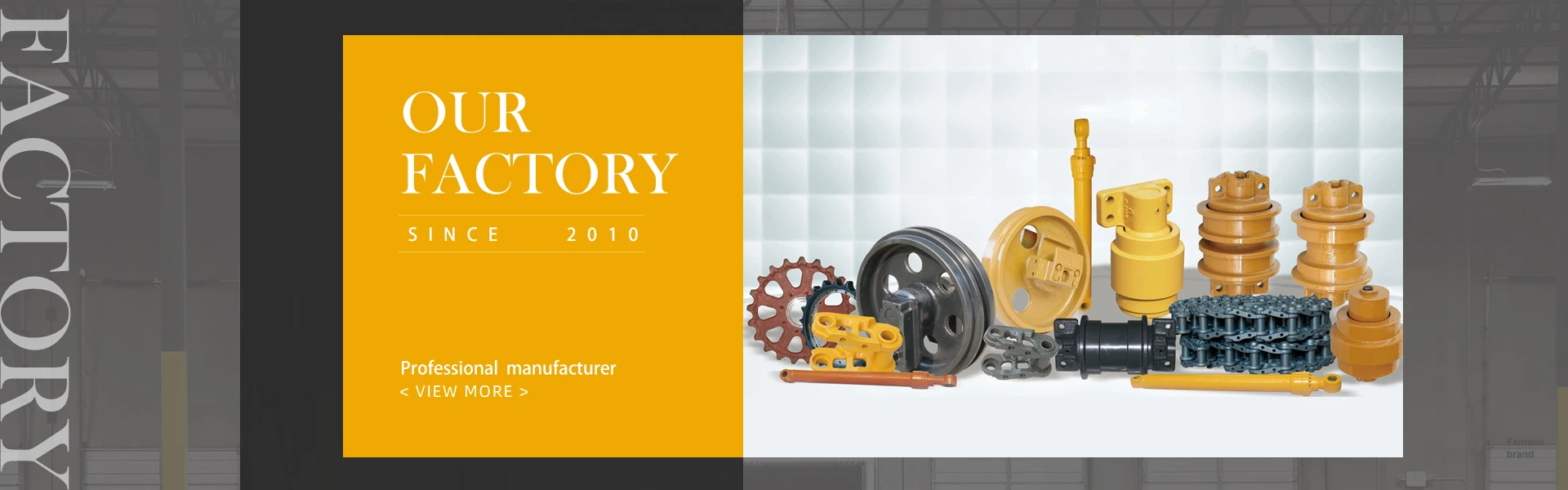

Hot Tags: cat345gc track adjuster assy, China, suppliers, manufacturers, factory, buy

Send Inquiry